Sidhant D. or Steven Spielberg... I can't tell!! Sidhant D. or Steven Spielberg... I can't tell!! Documentation and Branding are undeniable and deeply important aspects within any large-scale, visually-centered competition. Being able to receive recognition for your team's name and image is a top goal for a lot of teams. This phenomenon became apparent to me as I made my way through the dozens of aisles of 'pits' at Worlds (top championship for FIRST) in 2022. I was immediately drawn to the teams with tall, vibrant signage or those iconic, well-known teams with over-the-top accessories and names slapped onto everything from necklaces to first-aid-kits. It was clear that, aside from winning matches, getting your name out there was top priority. Seeing how Columbus Space Program has tried to stand apart from other teams by adopting our unique shade of green, we naturally have extended this importance of visibility to Media. Our Media team has been appraised as its own independent segment of the team, with a selective number of CSP members fully devoted to media, representing our image in a refined, yet authentic setting. The core facets of our Media team begin with pictures and graphic design. Pictures speak for themselves– real-time, raw imagery of how our team operates. Graphic design, however, is more complex, its roots running deep throughout the foundation of CSP. Graphic design, by default, entails the logos for teams, flags, and sub-programs meant to represent the impetus of our team. Signs are another staple to us and border the outskirts of our pit at competitions– aptly deemed Pit Signs. Having created a smooth system of production for these facets, CSP’s media team decided to heavily ramp up its diversification and level of content creation. In the last year, we have unveiled CAD With Connor, a YouTube series by our skilled, remote designer instructing aspiring CAD-ers on how to become proficient with design. Safety Tip of the Week is another video-based product, which appears on our Instagram (@frcteam4188) with the purpose of educating viewers on how to take the best precaution when around machinery. As a result. video-production made its way starkly past the confinements of just reveal or chairman's videos. And, in large part, CSP owes this transition to our two-year FRC veteran, Sidhant D. Sidhant's transition into Media can be described as a natural, puzzle-piece-like fit to the team. In the 2021-2022 build season, Sidhant recalls that he “was kinda running around mostly doing ‘programming’ amongst other things, but nothing fairly consistent.” However, in late February of 2022, he overheard another member, Jay, storyboarding a robot reveal. Later, Jay asked him for assistance with the video via Discord since Sidhant had previously mentioned having experience with video editing on Premiere Pro. After some shadowing and toying around with different video-editing concepts, Sidhant’s work was recognized by our head Coach at the time, who avidly praised his input on the robot-reveal video, swiftly beginning to include Sidhant in more media-centered conversations. Sidhant recalls how, as a result of this praise, he “committed to working on media from there [on] as some people liked [my work] which was really cool to see.” Sidhant has made significant contributions to our team in such a short amount of time. For one, CSP’s initiative to rebrand was carried out in large part by him through the redesign of the Columbus Space Program Flag and all FTC logos. In response to his physically issued work, Sidhant said it was surreal “seeing the actual flag in real life...[or] how the graphics I create on my computer can turn out.” Sidhant’s work indisputably reveals his natural draw towards creation. In gaining more insight from Sidhant on technique, he advised others interested in media to “keep everything organized by making several files for different footage, graphics, and other factors,” as this minimizes unnecessary stress in the future. He describes his personal process of graphic design as being differentiated into clear steps. He mentions that he sketches out his rudimentary ideas “in Photoshop and research[es] reference images for inspiration” but that, as time draws on, “the final product always ends up being something very different.” Nonetheless, amongst the trial and error often comes new understanding. After all, experimentation is essential to breeding systematic steps for more a efficient and progressive output. Sidhant's contributions amongst the general CSP media team's work divulges that our purpose and personality as a team is not void of a conversation-- we as integrated, yet self-sufficient individuals are recognized through these media efforts. We are more than the robot that races around the field with ‘4188’ on its sides-- that is but our surface.

0 Comments

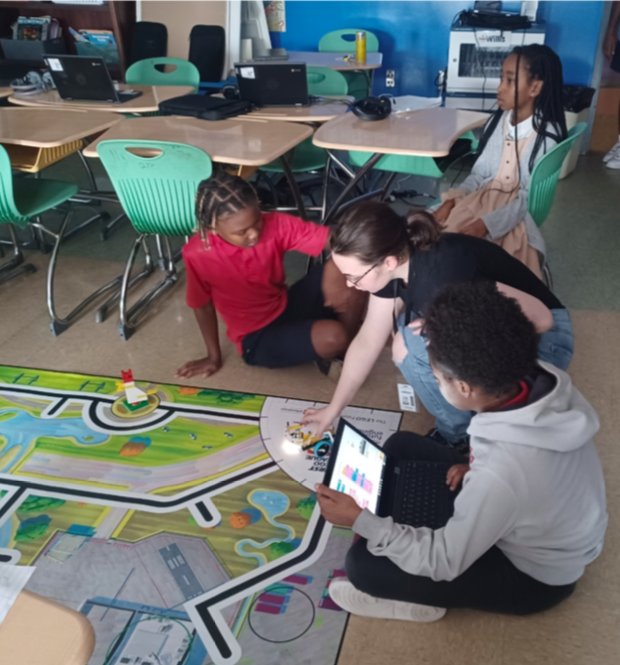

CNC router cutting out a climber 'hook' for Pyxis, 2022 CNC router cutting out a climber 'hook' for Pyxis, 2022 Computer-Aided Manufacturing, or CAM, is computer-controlled machinery integrated with software such as AutoCAD or Fusion360. The purpose of CAM is to automate the usual manufacturing process, using pre-programmed toolpaths to etch out a desired design on various raw materials– polycarb, aluminum, etc. CAM uses a sort of language converter produced from digitized data, called post-processing, that enables designs made in CAD, and then transferred to CAM, to be tangibly manufactured via a CNC machine (Computer Numerical Control). The CNC machine at Columbus Space Program’s HeadQuarters is a long metal table with a rigid arm jutting out over it, which controls the physical toolpaths. Accentured along the table are deep grooves from past cuttings and dozens upon dozens of unruly aluminum shavings to be swept up at the end of each day. Also attached to the router is a small table with the computer that inputs information taken from CAD to CAM, telling the machine its tasks. But, of course, none of this manufacturing would be able to happen without immensely focused human labor. CSP began to CNC in 2018 initially, but the bulk of the work done with it surfaced after COVID in late 2021 by our FTC team, Ecliptic. However, with no one professionally trained in operating it, the CNC router posed a huge learning curve, begging the question of whether it was worth relearning or not. Of course we can’t just waste machinery, but what also solidified the decision was the team constantly running into problems of non-precise holes and cuts. CAM and CNC would ensure custom boreholes and depressions that were near-perfect. CAM-ing and CNC-ing has undoubtedly allowed our team to test its creative limits, going beyond what was previously expected of us as well as guaranteeing more prototypes in less time. Actually, all parts now and in the future are intended to be completely CNC-ed if they are not electrically based. To make the longevity of CAM possible, we are training four rookies to be able to confidently use both the software and machinery. At all times in our history, CSP has intended to uplift innovation and independency, whether it be personal or creative expression (respectively), learning how to troubleshoot efficiently, or forming immersive and varied experiences for rookies (welding, soldering, graphic design etc.). CAM and the CNC router are each an extension of this concept, needing machinists to interpret technical drawings as well as sequence and refine software operations. CSP hopes to continue using CAM and CNC to increase the smoothness of workflow and the design-to-final-fabrication transition. When each of us took interest in or joined robotics, we relied on the advice and knowledge of others– whether that be in the form of YouTube videos, Reddit subposts, friends, or from current and past members of robotics. We all had a starting point, and none of us arrived where we are today without help. And, at Columbus Space Program, we make a point to never forget this. One of FIRST’s Core Values is “outreach.” Every team handles outreach differently and establishes opportunities based on their values and causes. But still… How can one characterize outreach? Outreach is defined as any unpaid volunteer work done by members of any team with the established purpose of enriching the surrounding community. CSP believes that no team should be barred from reaching their potential solely due to a lack of funds or resources, which is why, each season, we open up our practice field for other teams in Georgia to use if they would like to. Through the eleven FLL (First Lego League, K-8) and FTC (First Tech Challenge, 9-12) teams we mentor within Georgia, we are not only able to keep an eye on how the next generation of robotics progresses, we also use our personal skills to funnel knowledge back into this community– of which we were all once a part. Typically, when we mentor, we assign each member of a team to one specific ‘skills’ category– design/build, research/innovation programming, and awards. The FLL or FTC members are then sorted to one or more of the categories based on their own, personal interests. As student-mentors, we tailor our mentoring to the FLL or FTC teams’ preferences (individual learning, small-group learning or rotational learning). Current FLL member, Milan, exclaimed: “my favorite part of robotics is block coding. It’s a little hard at first, but it was cool to guess how to fix things and make it work.” (far left image) Current FLL member, Sai, emphasized that “organization in the build space is key to an organized and efficient team… We learned the hard way this year that we needed to section off our team into groups, lining up tasks like a queue, but mentoring has made it a lot easier to do so.” (far right image). With mentoring, CSP’s goal is to kick-start a cyclical learning process that sticks around throughout the years. Creating a solid, sustainable foundation allows these teams we have worked with to eventually operate independently, as with the FLL team at Richard’s Middle School we have mentored over the past few years. What’s more is our reach past FLL mentoring and into FTC. Students join robotics at different times in their lives and, even if they have experience, they may be moving to a school that does not possess an established team. This is why, in an effort to increase the longevity of Georgia’s robotics programs, CSP aims to continue mentoring throughout the levels of robotics– FLL all the way to FRC.

|

Archives

February 2024

Categories |

RSS Feed

RSS Feed